Perth, Australia-based robotics company FBR – formerly known as Fastbrick Robotics – has built its first two-storey house using its Hadrian X block-laying robot, which has been in development since 2015.

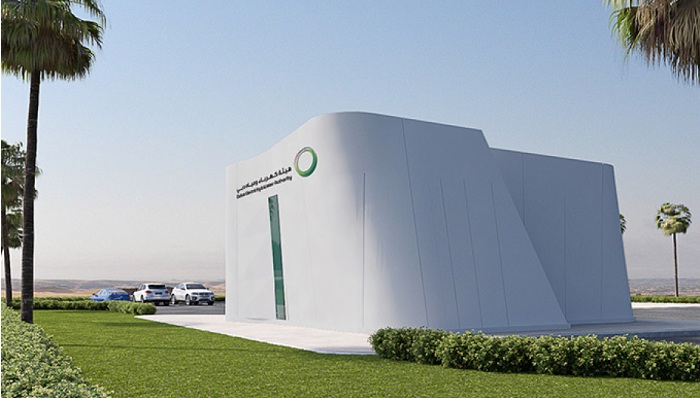

Located on FBR’s premises, the structure is of a style common in developing countries that FBR aims to target, including Mexico, the Middle East, North Africa and Asia.

It was the first time the robotic block-laying approach incorporated steel reinforced concrete columns and a concrete floor slab placed atop the structure’s first storey.

“In many parts of the world our customers want to be able to build two storey structures safely, quickly and efficiently, and we have now demonstrated that the Hadrian X can deliver on those customer needs,” said FBR chief executive Mike Pivac.

The technology, which received a $2m investment from Caterpillar in 2017, uses a 98-foot robotic arm mounted on a truck to place customised blocks fed up through the arm.

Hadrian uses a 98-foot robotic arm mounted on a truck to place customised blocks fed up through the arm (FBR). Its claw is guided by motion sensors following a digital blueprint, and can auto-correct its position 1,000 times a second.

A nozzle on the arm squirts a mortar, also customised. In June this year, FBR said Hadrian X could lay more than 200 blocks an hour, a 300% increase in speed compared with February 2019.