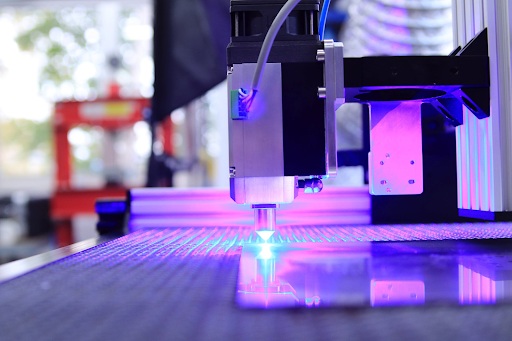

If you are looking to create a product prototype, there are several methods you can use. One of the most popular is rapid prototyping with CNC machines. This process lets you produce items quickly and inexpensively without having to wait long periods for your prototypes.

CNC stands for Computer Numerical Control. The machine is a computer-operated device capable of creating a three-dimensional physical item from a digital file. Here’s everything you need to know about the benefits of rapid prototyping with CNC machines.

What is Rapid Prototyping, and How Does it Work?

Rapid prototyping is when you take an item from a digital file to a physical product in the quickest time possible. The machine reads files created with computer-aided design programs, most commonly STL files. These are generally used for 3D printing but can be transferred into CNC machines as well.

These prototyping services differ from traditional prototyping because it uses a subtractive method rather than an additive one. With this type of rapid prototyping, you are cutting away at a block of material to create the desired design. With additive prototyping, you are adding material in layers until it takes shape.

How can rapid prototyping benefit your business?

If you are still on the fence about using rapid prototyping services for your product prototype, you need to consider the following benefits.

Speed

Rapid prototyping takes much less time than other methods of creating prototypes. For example, if you are using 3D printing to make your prototype, it could take several hours before you get the results that you want.

On the other hand, rapid prototyping with CNC machines can be done in a matter of hours. So while the build time for projects may vary depending on factors such as complexity and size, you will be able to get your prototype in a shorter amount of time than other methods.

Affordability

Rapid prototyping with CNC machines lets you produce your prototypes at an affordable cost. Other methods of creating prototypes can result in higher costs since these are often done in mass quantities. In addition, the more prototypes you need, the higher the cost will be to create them.

With rapid prototyping, you will only spend money on manufacturing your prototype one time. Using this method, you can produce just one prototype at a reduced price and then use that for testing purposes.

Customization

Since rapid prototyping services let you get your prototype in a matter of hours, you may find that the prototype produced is not exactly what you are looking for. You can get another prototype quickly so that it meets your specific needs without having to pay high costs to get multiple prototypes made.

You will be able to customize your product prototype by making adjustments to the digital file. This cannot be done with other methods, which means your prototype may not be exactly what you need. Once you make the desired changes, you can order another rapid prototyping job for this new design.

Quality

One of the benefits of using rapid prototyping with CNC machines is getting a product made with high-quality material. On the other hand, 3D printing produces plastic prototypes, which are not as long-lasting as the metals used with rapid prototyping services.

With rapid prototyping, you can choose between different types of materials for your prototype. For example, if you need to test the durability of your product under certain conditions, you can order an aluminum prototype. However, if you need to test for heat tolerance, aluminum is not the material best suited for that application since it melts easily when exposed to heat. Instead, titanium would be a better choice.

Reusability

Another benefit of rapid prototyping with CNC machines is that you can reuse your prototype. This lets you test multiple versions of your prototype to determine which design will work best for your product. You can make adjustments by changing the digital file and then order another rapid prototyping job.

This is not possible with other methods since they produce one-time-use prototypes thrown away after testing is completed. If you need to test multiple prototypes, it makes more sense to use rapid prototyping since you can reuse your prototype.

Conclusion

Rapid prototyping is an excellent option for those looking to test their product before making mass production runs. If you need your prototype quickly, this method will deliver the results you want much faster than other methods such as 3D printing or injection molding.

Rapid prototyping with CNC machines has many benefits and will provide you with a product prototype made from high-quality materials. Additionally, the quality of the prototype allows you to test your product in various ways so that you can adjust it before going into full production.